We are India based manufacturers of innovative and technologically advanced roofing, skylighting and roof ventilation products.

We are a skylight and roof ventilation design and development company. We offer turn key solutions to the roofing, roof ventilation and skylighting requirement of a wide spectrum of customers. We conceptualize, design, develop and deliver customized yet cost effective roofing, skylighting, roof ventilation solutions.

All our Products marketed and supplied under our Brand RHINO TUFF. Brand RHINO TUFF epitomises excellent zero-defect quality at an affordable price. Our Products adhere to the highest standards of quality and safety. We follow the best manufacturing and management practices and are ISO 9001: 2015 & ISO 14001 certified.

Most of our Products harness the energy of the sun and wind to naturally illuminate and naturally ventilate buildings.

They help their patrons save valuable financial resources which otherwise would have to be spent on forced ventilation and artificial light. They are maintenance free. They help create a healthy, congenial and productive work environment and thereby improving labour productivity and performance.

RHINO TUFF Products helps save power and our environment friendly. They can be used to build green, carbon neutral and energy efficient buildings. They can help reduce carbon emissions and mitigate the menace of climate change.

OUR BEGINNING

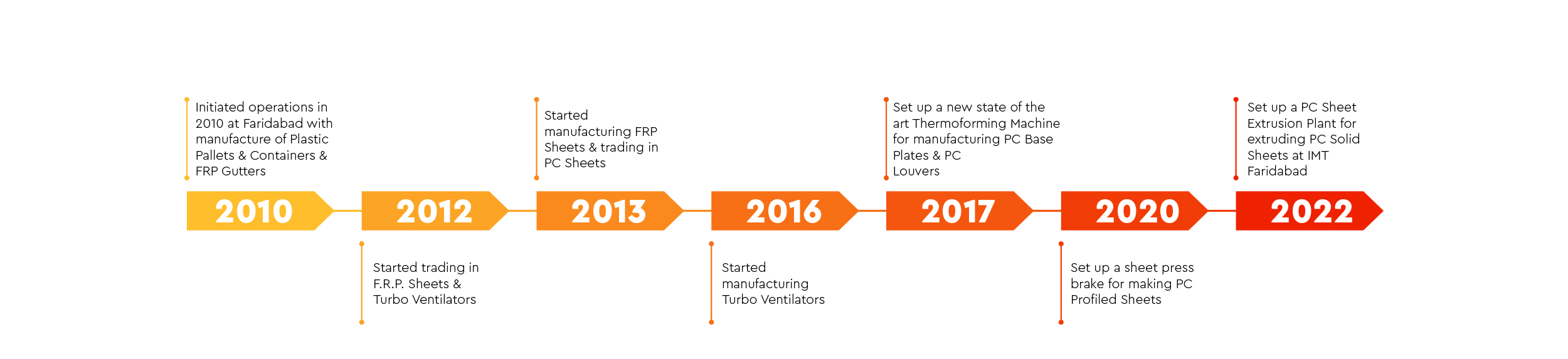

We were founded in the Year 2010 at Faridabad in India with the vision to become the world’s most valuable Company. Over the years, despite several challenges, we progressed rapidly towards the fulfilment of this cherished dream. Through the journey, our resolve to succeed became stronger and our passion for leadership, excellence and growth grew manifold.

For the first 8 years, we catered to the roofing, skylighting and roof ventilation needs of a wide spectrum of industry by offering FRP Roof Panels along with FRP Roof Accessories, FRP Skylights, FRP Drains along with Pipes and Pipe -Fittings and Automatic Rotators with FRP Soaker Plates.

In the Year 2017, with the setting up of a setting up of a state of the Thermoforming Plant, we started offering Poly - Soaker Plates for use with our Auto – Rotators, Polycarbonate Thermoformed Trapezoidal Skylight Panels & Polycarbonate Louvers.

In the Year 2022, as a part of our overall expansion strategy, we integrated backwards to set up a large state of the art Polycarbonate (PC) Sheet Extrusion Facility at Faridabad with an installed capacity of 3600 metric tons.